Double the bores.

Double the safety.

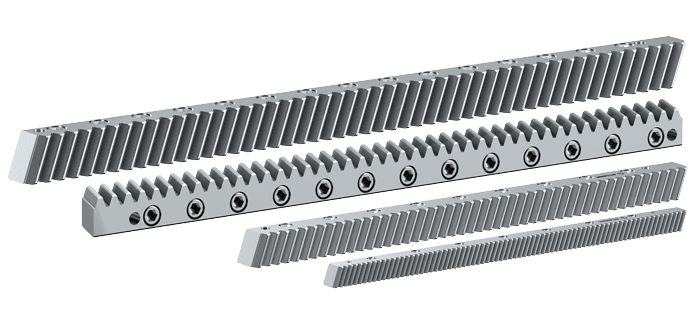

Precision racks with twice the bores!

Did you know that gear racks were originally used to place objects at different heights? For example, they were used in kitchens to perfectly position pots over fireplaces. As industrialization progressed, the gear rack became more important as a machine element and found its way into mechanical engineering.

Today, rack and pinion drives convert the rotary movements of gearboxes or motors into linear movements, or vice versa. The drive itself consists of a gear rack and its counterpart, the pinion. When the pinion is turned, the gear rack moves along its longitudinal axis, resulting in linear motion.

The challenge:

Possible shifting.

Gear racks must not shift out of place when forces are applied by the pinions. The pressing force of the screw fastenings counteracts this. In addition, gear racks are usually mounted with dowel pins at both ends of the racks. This process requires considerable effort. To ensure that the position is exactly right, the bores for the dowel pins must be made and then reworked with a reamer directly on the machine in the bolted-on state. This is extremely demanding, time-consuming work, especially on very complex systems.

The solution:

Double bores.

Our new precision gear racks with twice the bores eliminate the need for time-consuming pinning. The contact pressure on the machine body is doubled: Instead of every 125 millimeters as usual, gear racks are fastened again after just 62.5 millimeters. Although time-consuming pinning is not required, it remains an option thanks to the existing pin bores. This provides increased safety. And maximum ease of installation.

Figures. Data. Facts.

Our precision gear racks are available in various lengths and modules, for the highest demands on smooth operation and positioning accuracy.

- Module: 2 – 6 mm

- Max. feed force: 12.6 – 83.1 kN

- Helical, hardened, and smoothed

- Gearing quality 6 in accordance with DIN 3962-1

- Length: 500 mm, 1000 mm

„These smart, high-quality solutions have rounded off the lower end of our mechanical system. And for each user, everything fits together perfectly.”

– Matthias Eberle, Director of Business Development Asia Pacific at STOBER

“These smart, high-quality solutions have rounded off the lower end of our mechanical system. And for each user, everything fits together perfectly.”

– Matthias Eberle, Director of Business Development Asia Pacific at STOBER

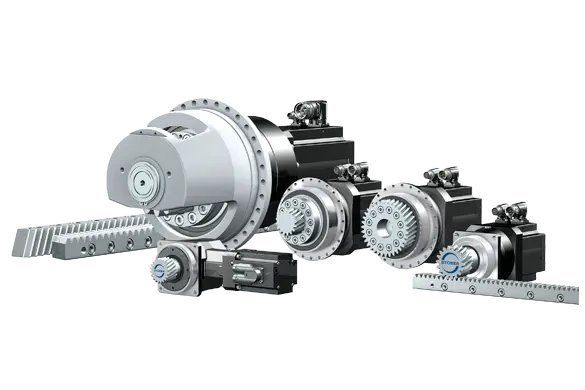

Consistent system concept.

From high flexibility to high force: Our innovative concept for rack and pinion drives, combined with planetary or helical bevel gearboxes and directly mounted servo motors, offers a perfectly coordinated system that can be flexibly adapted to a wide range of requirements in terms of load capacity and precision. It is ideal for applications in machine tools or automation and robotics.

Do you have any questions?

Please contact us! We would be happy to give you advice.

This might also interest you

With the innovative system concept for rack and pinion drives, STOBER has developed a compact, easy-to-use system with process reliability – ideal for automation & robotics.

Rack and Pinion Drives with Synchronous Servo Motors

From full rotation to linear: Innovative rack and pinion drives with synchronous servo motors from STOBER for ultra-compact, highly dynamic drive solutions.

Hot topics such as energy efficiency and eco-design are highly relevant at STOBER.

The new hybrid cable connects motors and drive controllers reliably up to 100 meters.