Designed to be absolutely practical:

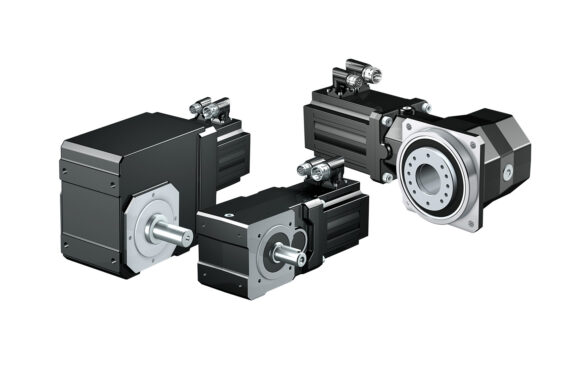

Helical bevel servo geared motors.

In this series, helical bevel gearboxes and synchronous servo motors form a compact unit featuring very convenient installation dimensions and a high power density.

The result is an extremely wide range of efficient design options for the packaging and machine tool industries as well as for automation and robotics.

- Helical bevel gearbox with EZ motor

- KEZ: Versatile and compact, for exceptional backlash stability

- KLEZ: Elegant, dynamic and completely without offset

- KSEZ: Strong, stable and with the highest possible power density

This coupling-free combination of a K series gearbox and EZ series synchronous servo motor reduces the space requirements and rotating masses, thereby lowering the total weight.

This increases the dynamics and saves costs.

All geared motors in this series feature high-quality helical gearing that guarantees unsurpassed smooth operation and backlash stability.

K gearboxes paired with EZ motors are a winning combination, especially due to the extremely compact geometry of the housing featuring an extremely low weight, a high volume performance and high torque.

The jointless, torsion-resistant block design and the directly attached EZ motor combine to form a highly rigid drive unit.

The motor shaft and gearbox output are on the same level, which makes the design of your machine or system so much simpler.

The geared motors of this series are used primarily when applications call for high dynamics, low weight and, above all, a small installation space.

Thanks to the technology that provides robust bearings and high-quality gearing, the gearboxes of the KS series are extremely durable and tip-resistant.

They can be used in continuous operation without any problems – even at high speed levels.

The advantage of direct attachment: the bevel gear stage, planetary gearbox and EZ motor form a compact unit featuring extremely convenient installation dimensions. Complemented by the square mounting flange, the geared motors can be mounted close together.

Power density

|

|||||

|

Price category

|

€ | € | € | € | € |

- Total ratio: 4 – 381

- Allowed acceleration torque: 23 – 13200 Nm

- Backlash: 1.5 – 12 arcmin

- Efficiency: 94 – 97%

Find your right fit!

Power density

|

|||||

|

Price category

|

€ | € | € | € | € |

- Total ratio: 4 – 32

- Allowed acceleration torque: 11 – 65 Nm

- Backlash: 16 – 25 arcmin

- Efficiency: 97%

Find your right fit!

Power density

|

|||||

|

Price category

|

€ | € | € | € | € |

- Total ratio: 6 – 100

- Allowed acceleration torque: 27 – 400 Nm

- Backlash: 4 – 6 arcmin

- Efficiency: 93 – 95%

Find your right fit!

- To the features of K gearboxes

- To the features of EZ motors

- To the features of KL gearboxes

- To the features of EZ motors

- To the features of KS gearboxes

- To the features of EZ motors

We get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn more| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Catalog Synchronous servo geared motors EZ | 14 | 442437 | 2025 03 | EN | 24.13 MB |

| Catalog STOBER compact | 06 | 442655 | 2024 10 | EN | 9.76 MB |

| Catalog Synchronous servo geared motors with redundant brake | 02 | 443311 | 2024 09 | EN | 17.32 MB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Operating manual KL10 - KL20 gear units and geared motors | 00 | 443363 | 2023 07 | EN | 1.74 MB |

| Operating manual KS40 - KS70 gear units and geared motors | 00 | 443362 | 2023 07 | EN | 1.74 MB |

| Operating manual K1 - K10 gear units and geared motors | 00 | 443364 | 2023 07 | EN | 3.06 MB |

| Safety instructions for synchronous servo motors synchronous servo geared motors | 00 | 443104 | 2018 07 | EN | 74.66 KB |

| Operating manual EZ EZHD EZHP EZS EZM synchronous servo motors | 01 | 443032 | 2019 05 | EN | 441.75 KB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Replacement parts list K10 helical bevel gear unit | 00 | 443455 | 2024 07 | EN | 1.33 MB |

| Replacement parts list MGS gears with pre-stage in mounting position 5 | 01 | 441491 | 2009 11 | EN | 50.87 KB |

| Replacement parts list K9 helical bevel gear unit | 01 | 442686 | 2018 03 | EN | 1.82 MB |

| Replacement parts list K8 helical bevel gear unit | 00 | 442692 | 2018 03 | EN | 1.86 MB |

| Replacement parts list K7 helical bevel gear unit | 00 | 443064 | 2018 03 | EN | 1.86 MB |

| Replacement parts list K6 helical bevel gear unit | 00 | 443073 | 2018 03 | EN | 1.80 MB |

| Replacement parts list K5 helical bevel gear unit | 00 | 443128 | 2018 10 | EN | 1.73 MB |

| Replacement parts list K2 K3 K4 helical bevel gear unit | 00 | 443131 | 2018 10 | EN | 1.63 MB |

| Lubricant fill volume | 17 | 441871 | 2023 10 | EN | 2.18 MB |

| Replacement parts list K1 helical bevel gear unit | 00 | 443132 | 2018 09 | EN | 1.37 MB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Certificate Free of CCC | 35 | 442072 | 2025 04 | EN | 261.03 KB |

| EU declaration of conformity synchronous servo motors and synchronous geared motors ED EK EZ | 02 | 443089 | 2024 03 | EN | 73.57 KB |

| UK declaration of conformity synchronous servo motors and synchronous servo geared motors EZ ED EK LM | 00 | 443297 | 2021 10 | EN | 71.46 KB |

| Certificate UL - cURus synchronous servomotors EZ EZS EZM EZHD EZHP | 00 | 443097 | 2016 12 | EN | 1.44 MB |

Take advantage of the expertise of our application engineers in the Sales Centers or contact our first level support.

OPENsystemsupport@stoeber.de

With SERVOsoft®, you have a tool at your fingertips that lets you design your drive systems with precise scaling in just a few steps. Electrical as well as mechanical design, and simple and fast at the same time.

OPENWith the intuitive STOBER product configurator, you can filter, compare, save and share the right drive solutions with ease.

OPENAre you looking for CAD data? With the STOBER CAD tool, the drawings you need are ready for download in just a few clicks.

OPENSTOBER is present in over 40 countries worldwide with 12 subsidiaries and 80 service partners. No matter where, no matter when, we’re always at your service and on the move!

OPENDo you need competent help with replacement parts, replacement drives, repairs and retrofitting? Feel free to contact us! We also offer a 24-hour hotline for urgent cases.

OPENFor us, TEAMWORK is a huge priority.

“At WINDMÖLLER & HÖLSCHER, collaborative partnership and trust are huge priorities. With STOBER, we have a strategic partner who also lives these by principles.”

– Christian Klein, Strategic Purchasing, WINDMÖLLER & HÖLSCHER KG

STOBER Product ID.

Do you need operating and assembly instructions, replacement part lists or notes on technical features of our products?

Thanks to the STOBER Product ID., you can get the information you need quickly and easily.

This might also interest you

Offset Helical Servo Geared Motors

Looking for a geared motor for tight spaces? With a large axial distance?

Helical Bevel Geared Lean Motors

Save on everything without reducing performance and energy efficiency! STOBER helical bevel gearboxes combined with STOBER Lean motors.

6th Generation Drive Controllers

Whether for high-performance systems, highly efficient multi-axis applications or compact modules – the 6th generation from STOBER always has the right drive controller on hand.