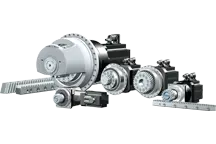

From high flexibility to high force: Rack and pinion drives.

With the innovative system concept for rack and pinion drives, STOBER has developed a compact, easy-to-use system with process reliability that is precisely tailored to the application areas of machine tools, automation and robotics.

The special highlights are the very flexible and efficient ZV series and the ZTRS series with a supporting bearing holder – for maximum feed force!

- Highly rigid rack and pinion drives as ready-to-install solutions

- ZV: High flexibility for automation and robotics

- ZR: High speed due to high feed velocities

- ZTR: High performance for demanding drive concepts

- ZTRS: High force for maximum power density

All STOBER gear rack and pinion drives are ready-to-install solutions in a wide variety of combinations – adapted to the different requirements in terms of load capacity and precision.

With the helical toothed ZV series you can choose what you like – the pinion position is either at the shaft end or the shaft shoulder.

This series also has an impressive backlash-free, positive-locking shaft-hub connection.

ZV rack and pinion drives can be attached to P, PE, K, KS or KL gearboxes.

The ZR series features large, helical pinions with a bolt circle, which allow high feed velocities.

The pinions are mounted without an additional flange, which is one reason for the attractive price-performance ratio.

The very precise and also very high-performance ZTR series features small pinion diameters, high linear rigidity and lower torques.

The pinions with the welded screw flange can be easily mounted and dismounted. The ZTR series is therefore ideal for feed axes of machine tools where the supporting bearing holder is an interfering contour. This means gantry machines, vertical and horizontal lathes or milling and drilling centers.

The rack and pinion drives can be combined with PH and PHV series gearboxes.

Developed by STOBER, the bolted supporting bearing holder with stiffening ribs on the inner contour makes it possible to use the full gearbox torque in a rack and pinion drive for the first time. As a result, this also optimizes the power density and rigidity. To determine the drive, the relevant variable is no longer the tilting torque, but the torque that is actually required.

ZTRS is ideal for feed axes of machine tools, laser machines and highly dynamic and precise handling systems.

The rack and pinion drives can be combined with the PH, PHQ and PHV series gearboxes.

4 Zahnstangen

- Module: 2 – 6 mm

- Gearing quality 6

- Helical, hardened, and smoothed

- Length: 500 and 1000 mm

Find your right fit!

0 Technical Data Zahnstangentriebe ZV

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 4 mm

- Number of teeth: 16 – 25

- Acceleration feed force: 1.7 – 15 kN

- Permitted feed velocity: 0.14 – 5.3 m/s

- Linear backlash: 8 – 44 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 3 mm

- Number of teeth: 16 – 25

- Acceleration feed force: 1.7 – 6.1 kN

- Permitted feed velocity: 0.14 – 4.5 m/s

- Linear backlash: 40 – 83 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 4 mm

- Number of teeth: 18 – 25

- Acceleration feed force: 3.2 – 11 kN

- Permitted feed velocity: 0.07 – 3 m/s

- Linear backlash: 37 – 44 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 mm

- Number of teeth: 16 – 20

- Acceleration feed force: 1.3 – 2.7 kN

- Permitted feed velocity: 0.33 – 3.3 m/s

- Linear backlash: 99 – 123 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 4 mm

- Number of teeth: 18 – 25

- Acceleration feed force: 2.7 – 15 kN

- Permitted feed velocity: 0.06 – 3.8 m/s

- Linear backlash: 12 – 111 μm

Find your right fit!

|

Zahnstange Leistungsdichte:

|

|||||

|

Zahnstange Preisklasse:

|

€ | € | € | € | € |

- Modul: 5 – 8 mm

- Zähnezahl: 19

- Beschleunigungsvorschubkraft: 67 – 77 kN

- Zul. Vorschubgeschwindigkeit: 0,21 – 0,49 m/s

- Lineares Spiel: 15 – 56 μm

Technical Data Zahnstangentriebe ZR

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 4 mm

- Number of teeth: 30 – 40

- Acceleration feed force: 3.1 – 16 kN

- Permitted feed velocity: 0.29 – 6.7 m/s

- Linear backlash: 10 – 56 μm

Find your right fit!

Technical Data Zahnstangentriebe ZTR

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 2 – 6 mm

- Number of teeth: 12 – 32

- Acceleration feed force: 6.5 – 67 kN

- Permitted feed velocity: 0.11 – 4.7 m/s

- Linear backlash: 4 – 44 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 5 – 6 mm

- Number of teeth: 16 – 19

- Acceleration feed force: 56 – 67 kN

- Permitted feed velocity: 0.2 – 0.39 m/s

- Linear backlash: 15 – 44 μm

Find your right fit!

Technical Data Zahnstangentriebe ZTRS

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 3 – 8 mm

- Number of teeth: 15 – 32

- Acceleration feed force: 20 – 79 kN

- Permitted feed velocity: 0.2 – 4.7 m/s

- Linear backlash: 8 – 56 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 8 mm

- Number of teeth: 19

- Acceleration feed force: 124 kN

- Permitted feed velocity: 0.06 – 1.1 m/s

- Linear backlash: 70 μm

Find your right fit!

|

Power density:

|

|||||

|

Price category:

|

€ | € | € | € | € |

- Module: 5 – 8 mm

- Number of teeth: 19

- Acceleration feed force: 67 – 77 kN

- Permitted feed velocity: 0.21 – 0.49 m/s

- Linear backlash: 15 – 56 μm

Find your right fit!

0 ZV rack and pinion drive features

- Output pinion:

- Helical gearing, case-hardened and smoothed

- Gearing quality 6

- Can be mounted on the shaft with toothing flush with the shaft end or with the shaft shoulder

- Backlash-free shaft-hub connection, shrink bonded and feather-keyed

- Optional axial locking

- Bearing: Standard, axial or radial reinforced

- Mounting position: Any

- Lubricants and maintenance:

- ZV rack and pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0

- P gearboxes: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- FlexiAdapt (MF) with bellow coupling and integrated thermal length compensation

- ServoStop (MB) with plug-in coupling (jaw coupling) and integrated spring-loaded brake

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

- Output pinion:

- Helical gearing, case-hardened and smoothed

- Gearing quality 6

- Can be mounted on the shaft with toothing flush with the shaft end or with the shaft shoulder

- Backlash-free shaft-hub connection, shrink bonded and feather-keyed

- Optional axial locking

- Mounting position: Any

- Lubricants and maintenance:

- ZV rack and pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0

- PE gearboxes: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

- Output pinion:

- Helical gearing, case-hardened and smoothed

- Gearing quality 6

- Can be mounted on the shaft with toothing flush with the shaft end or with the shaft shoulder

- Backlash-free shaft-hub connection, shrink bonded and feather-keyed

- Optional axial locking

- Backlash: Standard, Class I or Class II

- Mounting position: Any

- Lubricants and maintenance:

- ZV rack and pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0

- K gearboxes: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling

- ServoStop (MB) with plug-in coupling (jaw coupling) and integrated spring-loaded brake

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

- Output pinion:

- Helical gearing, case-hardened and smoothed

- Gearing quality 6

- Can be mounted on the shaft with toothing flush with the shaft end or with the shaft shoulder

- Backlash-free shaft-hub connection, shrink bonded and feather-keyed

- Optional axial locking

- Mounting position: Any

- Lubricants and maintenance:

- ZV rack and pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0

- KL gearboxes: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- Square motor adapter (MQ) with plug-in coupling (jaw coupling)

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

- Output pinion:

- Helical gearing, case-hardened and smoothed

- Gearing quality 6

- Can be mounted on the shaft with toothing flush with the shaft end or with the shaft shoulder

- Backlash-free shaft-hub connection, shrink bonded and feather-keyed

- Optional axial locking

- Bearing: Standard, axial or radial reinforced

- Mounting position: Any

- Lubricants and maintenance:

- ZV rack and pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0

- KS gearboxes: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- Recommended motor for direct attachment: Particularly efficient in combination with STOBER motors of the EZ series

0 ZR rack and pinion drive features

- Gear racks: You can obtain the gear racks that exactly match all our products from our cooperation partner ATLANTA

- Output pinion:

- Helical gearing, case-hardened and smoothed

- Gearing quality 5

- Mounting position: Any

- Lubricants and maintenance:

- ZR rack-and-pinion drive: Lubrication is the responsibility of the customer; we recommend high-quality greases based on synthetic oils, NLGI class 0

- PH gearbox: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- FlexiAdapt (MF) with bellow coupling and integrated thermal length compensation

- ServoStop (MB) with plug-in coupling (jaw coupling) and integrated spring-loaded brake

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

0 ZTR rack and pinion drives features

- Gear racks: You can obtain the gear racks that exactly match all our products from our cooperation partner ATLANTA

- Output pinion:

- Case-hardened and smoothed

- Gearing quality 5

- Optional radial runout ≤ 10 µ

- Mounting position: Any

- Lubricants and maintenance:

- ZTR rack-and-pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0

- PH gearbox: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- FlexiAdapt (MF) with bellow coupling and integrated thermal length compensation

- ServoStop (MB) with plug-in coupling (jaw coupling) and integrated spring-loaded brake

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

- Gear racks: You can obtain the gear racks that exactly match all our products from our cooperation partner ATLANTA

- Output pinion:

- Case-hardened and smoothed

- Gearing quality 5

- Optional radial runout ≤ 10 µ

- Mounting position: Any

- Lubricants and maintenance:

- ZTR rack-and-pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0

- PHV gearboxes: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- ServoStop (MB) with plug-in coupling (jaw coupling) and integrated spring-loaded brake

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

0 ZTRS rack and pinion drive features

- Gear racks: You can obtain the gear racks that exactly match all our products from our cooperation partner ATLANTA

- Support bearing holder:

- Robust cast housing, closed protective design, stiffness optimized by internal ribbing

- Maximum feed force, minimized bending, increased service life

- Output pinion:

- Case-hardened and smoothed

- Gearing quality 5

- Optional radial runout ≤ 10 µ

- Mounting position: Any

- Lubricants and maintenance:

- ZTRS rack-and-pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0 Optional lubrication with felt gear; connection option for central lubrication or lubricator

- PH gearbox: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- FlexiAdapt (MF) with bellow coupling and integrated thermal length compensation

- ServoStop (MB) with plug-in coupling (jaw coupling) and integrated spring-loaded brake

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

- Gear racks: You can obtain the gear racks that exactly match all our products from our cooperation partner ATLANTA

- Support bearing holder:

- Robust cast housing, closed protective design, stiffness optimized by internal ribbing

- Maximum feed force, minimized bending, increased service life

- Output pinion:

- Case-hardened and smoothed

- Gearing quality 5

- Optional radial runout ≤ 10 µ

- Mounting position: Any

- Lubricants and maintenance:

- ZTRS rack-and-pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0 Optional lubrication with felt gear; connection option for central lubrication or lubricator

- PHV gearboxes: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- ServoStop (MB) with plug-in coupling (jaw coupling) and integrated spring-loaded brake

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

- Gear racks: You can obtain the gear racks that exactly match all our products from our cooperation partner ATLANTA

- Support bearing holder:

- Robust cast housing, closed protective design, stiffness optimized by internal ribbing

- Maximum feed force, minimized bending, increased service life

- Output pinion:

- Case-hardened and smoothed

- Gearing quality 5

- Optional radial runout ≤ 10 µ

- Mounting position: Any

- Lubricants and maintenance:

- ZTRS rack-and-pinion drive: Lubrication is the customer’s responsibility; we recommend high-quality greases based on synthetic oil, NLGI class 0 Optional lubrication with felt gear; connection option for central lubrication or lubricator

- PHQ gearboxes: CLP HC ISO VG 150 synthetic lubricant; lubricated for life and maintenance-free

- Paint: RAL 9005 Jet black

- Motor adapter:

- EasyAdapt (ME) with clamp coupling, optionally with a large motor plate (MEL)

- FlexiAdapt (MF) with bellow coupling and integrated thermal length compensation

- ServoStop (MB) with plug-in coupling (jaw coupling) and integrated spring-loaded brake

- Recommended motor for direct attachment: Particularly efficient in combination with a STOBER EZ series motor

- Portal milling

- Horizontal machining units

- Pick and place

- Laser cutting

- Tube bending

- Sheet metal bending

- 7th axis

- Vertical turntables

- Horizontal turntables

We get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn moreWe get your visions moving – in various industries and markets worldwide.

Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

Learn more| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Catalog rack and pinion drives | 06 | 443137 | 2024 04 | EN | 8.85 MB |

| Catalog STOBER compact | 06 | 442655 | 2024 10 | EN | 9.76 MB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Operating manual KL10 - KL20 gear units and geared motors | 00 | 443363 | 2023 07 | EN | 1.74 MB |

| Operating manual KS40 - KS70 gear units and geared motors | 00 | 443362 | 2023 07 | EN | 1.74 MB |

| Operating manual P23 - P93 gear units and geared motors | 00 | 443356 | 2023 07 | EN | 1.57 MB |

| Operating manual PHV94-PHV104 gear units geared motors | 00 | 443355 | 2023 02 | EN | 1.66 MB |

| Operating manual PH33-PH83 PH94-PH104 gear units geared motors | 00 | 443354 | 2023 02 | EN | 1.70 MB |

| Operating manual PHQ43-PHQ83 PHQ94-PHQ124 gear units geared motors | 00 | 443353 | 2023 02 | EN | 1.74 MB |

| Operating manual PE22 - PE52 gear units and geared motors | 00 | 443252 | 2021 03 | EN | 775.46 KB |

| Operating manual K1 - K10 gear units and geared motors | 00 | 443364 | 2023 07 | EN | 3.06 MB |

| Operating manual gear racks | 00 | 443392 | 2024 04 | EN | 1.75 MB |

| Safety instructions for gear units | 00 | 443108 | 2018 07 | EN | 70.76 KB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Lubricant fill volume | 17 | 441871 | 2023 10 | EN | 2.18 MB |

| Title | Version | ID | Date | Language | Size / Type | |

|---|---|---|---|---|---|---|

| Declaration of Incorporation gear units | 01 | 442718 | 2024 03 | EN | 68.12 KB |

| UK declaration of incorporation gear units | 00 | 443299 | 2021 10 | EN | 74.12 KB |

Take advantage of the expertise of our application engineers in the Sales Centers or contact our first level support.

OPENsystemsupport@stoeber.de

With SERVOsoft®, you have a tool at your fingertips that lets you design your drive systems with precise scaling in just a few steps. Electrical as well as mechanical design, and simple and fast at the same time.

OPENWith the intuitive STOBER product configurator, you can filter, compare, save and share the right drive solutions with ease.

OPENAre you looking for CAD data? With the STOBER CAD tool, the drawings you need are ready for download in just a few clicks.

OPENSTOBER is present in over 40 countries worldwide with 12 subsidiaries and 80 service partners. No matter where, no matter when, we’re always at your service and on the move!

OPENDo you need competent help with replacement parts, replacement drives, repairs and retrofitting? Feel free to contact us! We also offer a 24-hour hotline for urgent cases.

OPENQuality products with long service life.

“At MEBA, we value high-quality end products. Consequently, we need equally high-quality products to be installed in our machines. That’s exactly what we get from STOBER: quality products with a long service life.”

– Hubert Rauschmaier, Purchasing Manager Technical Purchasing, MEBA Metall-Bandsägemaschinen GmbH

Worldwide availability.

STÖBER is present in over 40 countries worldwide with 13 locations and 80 service partners.

No matter where, no matter when, we’re always at your service and on the move!

This might also interest you

Synchronous Servo Motors for Screw Drives

Super-compact motors. Ideal for universal attachment to threaded spindles and threaded nuts with a flange.

6th Generation Drive Controllers

Whether for high-performance systems, highly efficient multi-axis applications or compact modules – the 6th generation from STOBER always has the right drive controller on hand.